Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Highlight | naut chain Conveyor Belt Accessories,roller Conveyor Belt Accessories,naut steel Composite Production Line |

||

|---|---|---|---|

Products Categories

- Steel Belts

- Steel Belt for Chemical Industry

- Steel Belt for Food Industry

- Steel Belt for Composition Material Industry

- Belt Systems

- Steel Belt Cooling Systems

- Pastillator

- Steel Belt Pastillator

- Strip Cooler

- Flaking Cooler

- Single Belt Flaking Systems

- Pastillator

- Composite Production Line

- Food Processing Conveyor Systems

- Steel Belt Cooling Systems

- Hot Products

Roller Chain Press

Product Details

Naut Roller chain continuous double steel belt press system, including: automatic loading device, preheating part, hot melting and recombination part, continuous thicknessing part, cooling and heating solidifying part, cutting and packing part.

Roller chain continuous double steel belt press system is complicated, requires a high quality chain roller, you must keep the chain roller work with press in the same time together perfectly, application can be required highly the uniform pressure and temperature products.

|

roller chain press |

roller chain press systems |

Material:

Carbon steel H-shaped steel and other spare parts.

Zinc rich primer,The appearance color can depend on the customer to provide the metallic paint of the color card.

Characteristic:

Uniform pressure, roller chain accuracy is high

Finished products' temperature is uniform

Intelligent pressure system can adjust according to product shape automatically.

Meet ideal product accuracy compared to fixed roller.

Over 5 years usage time

Max.temperature can be 450℃

Structure:

The Roller chain continuous double steel belt press by Naut design and manufacture, the main parts are the hub, pressure roller, heating plate, lifting mechanism, hydraulic system, bearings and steel belt.

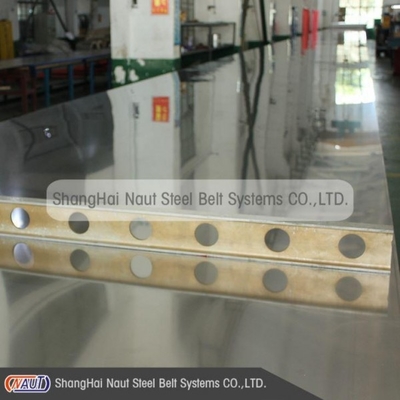

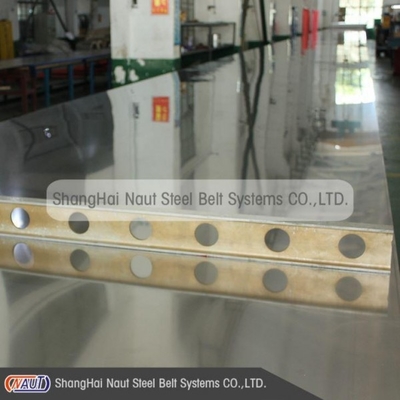

Roller chain blanket is connected by many 12.5mm diameter roller. Roller length varies, appears wavy structure for uniform pressure distribution, no mark on the presses plate surface.

Principle:

Sheet thickness depend on the space between the upper belt and lower belt. and the side preventsealing is mainly used to determine the width of the plate.

Then, after thecontrollablepolymerization, solidification and cooling processes, the products is cut into the desired specificationsby the longitudinal and transverse cutting knife.

Machining:

Raw material- film laying device- working table- enter the front tile press(hub temperature of 180℃)- enter the heating area of 300℃- material melting- enter the thicknesss area- into the cooling area- into the sawing line- cutting edge- scrap collecting- diagonalcutting and final products.

Product Usage:

Naut double belt presses can working continuous pressure heating and cooling procedure, can be used in the production of glass fiber, carbon fiber composite materials, interwoven compressed glass fiber, carbon fiber mat, fabric or thermoplastic material.

Previous: Roller Press

Next: Thin Film Casting Machine

Inquiry

|

Your Name:

|

|

|

*E-mail:

|

|

|

Phone:

|

|

|

Company:

|

|

|

Title:

|

|

|

*Content:

|

|

|

Send

|

-

High Strength Austenitic Stainless Steel Belt

-

High Strength Martensitic Stainless Steel Belt

-

Wax Pastillator

-

Sulfur Pastillator

-

Hot Melt Strip Cooler

-

MSS-1650 Stainless Steel Conveyor Belt