Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Brand | Naut | ||

|---|---|---|---|

| High Light | naut sus304 Steel Belt Cooling,naut carbon Steel Belt Cooling,naut Resin Pastillator |

||

Products Categories

- Steel Belts

- Steel Belt for Chemical Industry

- Steel Belt for Food Industry

- Steel Belt for Composition Material Industry

- Belt Systems

- Steel Belt Cooling Systems

- Pastillator

- Steel Belt Pastillator

- Strip Cooler

- Flaking Cooler

- Single Belt Flaking Systems

- Pastillator

- Composite Production Line

- Food Processing Conveyor Systems

- Steel Belt Cooling Systems

- Hot Products

Resin Pastillator

Product Details

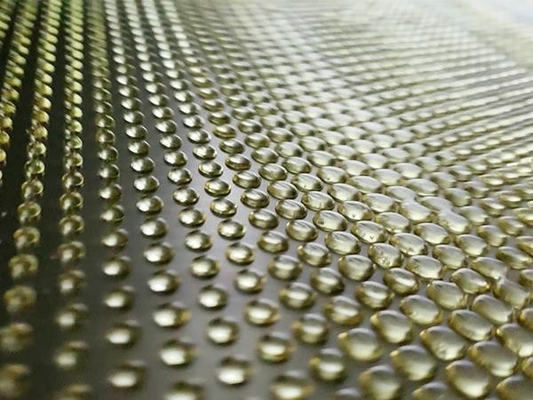

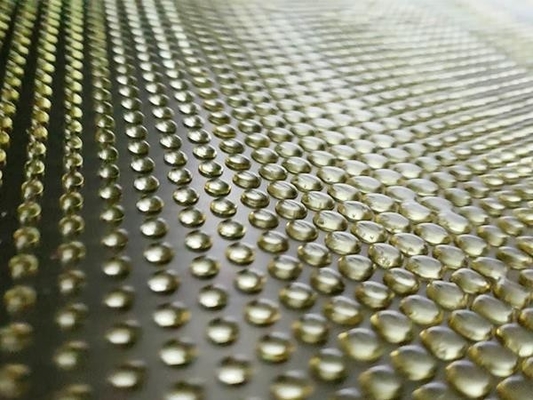

Naut Resin pastillator machine takes use of material's low melting point. According to the molten product's viscosity range, Via special over flow weir feeder, the molten product is loaded on the below constantly moving belts, the steel belt is sprayed on the underside with water from nozzles carefully positioned to ensure uniform cooling, on the cooling effects of water spray above or below the belt, the melt is cooled and solidified to flakes when conveying and moving.

|

resin pastillator |

resin pastillator machine |

resin pastillator machine line |

Material:

SUS304 stainless steel, Carbon steel, Zinc coated carbon steel,and other spare parts.

Characteristic:

Granulation machine, single steel belt granulation, chemical granulation, high corrosion, high speed, High efficiency, high strength, high capacity, high quality, Customized, low price.

Structure:

Single steel belt resin pastillator: Granulation head, Steel belt cooler machine, Steel belt, Control system, and other machine parts, Custom made parts.

Product Usage:

For material processing, heating, cooling, Solidification, for the chemical industry, Resin pastillator, pastillator for chemical, chemical granulation, granulation machine, resin granulation.

-According to the material's low melting and the molten product's viscosity range, via special over flow weir feeder,the molten product is loaded on the below constantly moving belts, the steel belt is sprayed on the underside with water from nozzle carefully positioned to ensure uniform cooling, on the cooling effects of water spray above or below the belt, the melt is cooled and solidified to flakes when conveying and moving. According to different material feature and capacity requirement, you can choose single belt cooling system and large capacity cooling system.

Previous: Wax Pastillator

Next: Sulfur Pastillator

Inquiry

|

Your Name:

|

|

|

*E-mail:

|

|

|

Phone:

|

|

|

Company:

|

|

|

Title:

|

|

|

*Content:

|

|

|

Send

|

-

Food Grade Stainless Steel Belt

-

Baking Oven Carbon Steel Belt

-

Chocolate Pastillator

-

Thin Film Casting Machine

-

Artificial Marble Production Line

-

ASS-1000 Stainless Steel Conveyor Belt